Meet Ameriwest Technology, Inc. (ATI) Plastics

At ATI Plastics, we are dedicated to the perfection needed to bring you the finest product possible at a reasonable cost. Your project, and ultimately the satisfaction of our customers, is our top priority. That’s why we go beyond simply meeting industry specifications, tolerances and aesthetics to produce top quality products. If you are in need of a custom plastic solution for you or your business we welcome the opportunity to lend our expertise.

What We Can Do For You

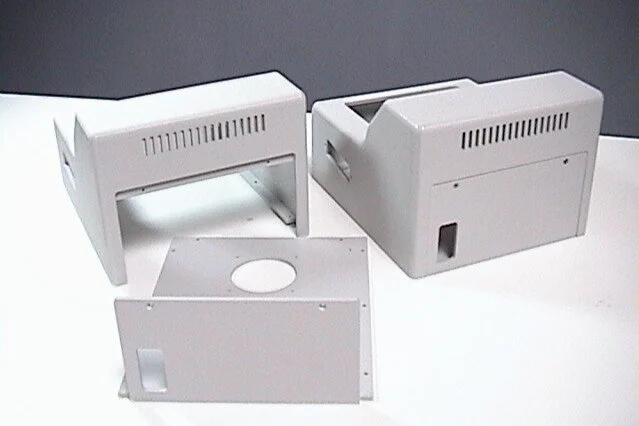

Vacuum Forming is when a sheet of plastic material is heated to pliability, then pressed against a 3D mold by vacuuming out the air between the sheet and the mold. Advantages include large, cost effective parts and high levels of detail.

Plastic Fabrication is the design, manufacture, or assembly of plastic materials using a wide range of tools, machinery and techniques include cutting, drilling, taping, bending, gluing, routing and polishing.

Starting from custom 3D modeling done in-house, the plastic machining process involves high precision cutting, drilling and taping of plastic materials to create custom parts such as specialized lab-ware, cooling systems, customized robotic solutions, and more.

Let us handle your plastic welding of materials such as PVC, Polyethylene, Polypropylene and more. Our meticulous welding process has resulted in top quality fume hoods, spill containment trays, material storage systems, and other specialized safety equipment.

Utilizing one vendor to design, manufacture,and assemble your prototype and production runs will save time and money. We provide assembly services both for in-house and out-sourced fabricated parts, taking the time to ensure efficiency and accuracy for your peace of mind.

From complex surfaces to simple shapes, all of your 3 & 5 axis CNC routing work receives our diligent attention to detail in order to ensure that all industry tolerances are met or exceeded. We can handle large production runs, as well as precise profiling requirements and the creation of detailed surfaces.

We can help you develop your product every step of the way. From the first sketches, to the prototypes, to the final product, you can be sure that the process is thoroughly managed to save you time and money.

At ATI, we can assist you in conceptual and design stages of your product. Our team will work closely with you in developing your products idea into a tangible model, drawing, or file while maintaining its design integrity and, above all, functionality.

Realize and communicate the appearance of your finished part before it’s made to both explore your options before prototyping and have the right materials to attract potential investors, funding, or customers.

“Through the use of precision equipment and tools the experienced staff at Ameriwest is able to meet and exceed specifications, tolerances, and aesthetics necessary to satisfy customers in every application.”

Let’s Get Started.

Use the form below to contact us regarding your plastic consulting, design, and manufacturing needs. Please provide us with your preferred contact information and a brief review of how we can help, and we will get back to you within 1 business day.

You can also call us at the office M-F from 8-4:30 at 760.747.9619