AMS Filling Systems

We Turn Your Powder Into Profits

AMS Filling Systems is a forward-thinking, design-driven filling equipment manufacturer. Since 1986, we have led the way in innovative design, manufacturing and servicing.

Our Solutions

Solving the Toughest Filling Challenges

At AMS, our focus and priority is our service commitment to our customers. We understand that one size does not fit all when it comes to filling solutions. We develop and deploy some of the most precise filling machines in response to the most demanding requirements. We have the expertise and ability to design and manufacture custom solutions while offering a level of service unmatched in the industry. Let us identify the precise filling system required to meet your company’s needs.

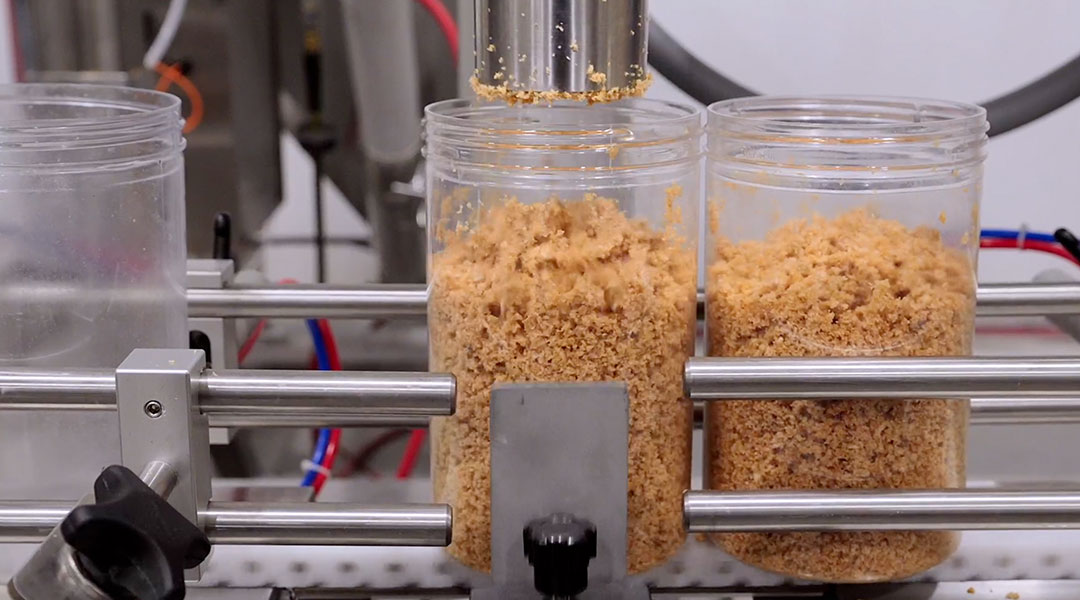

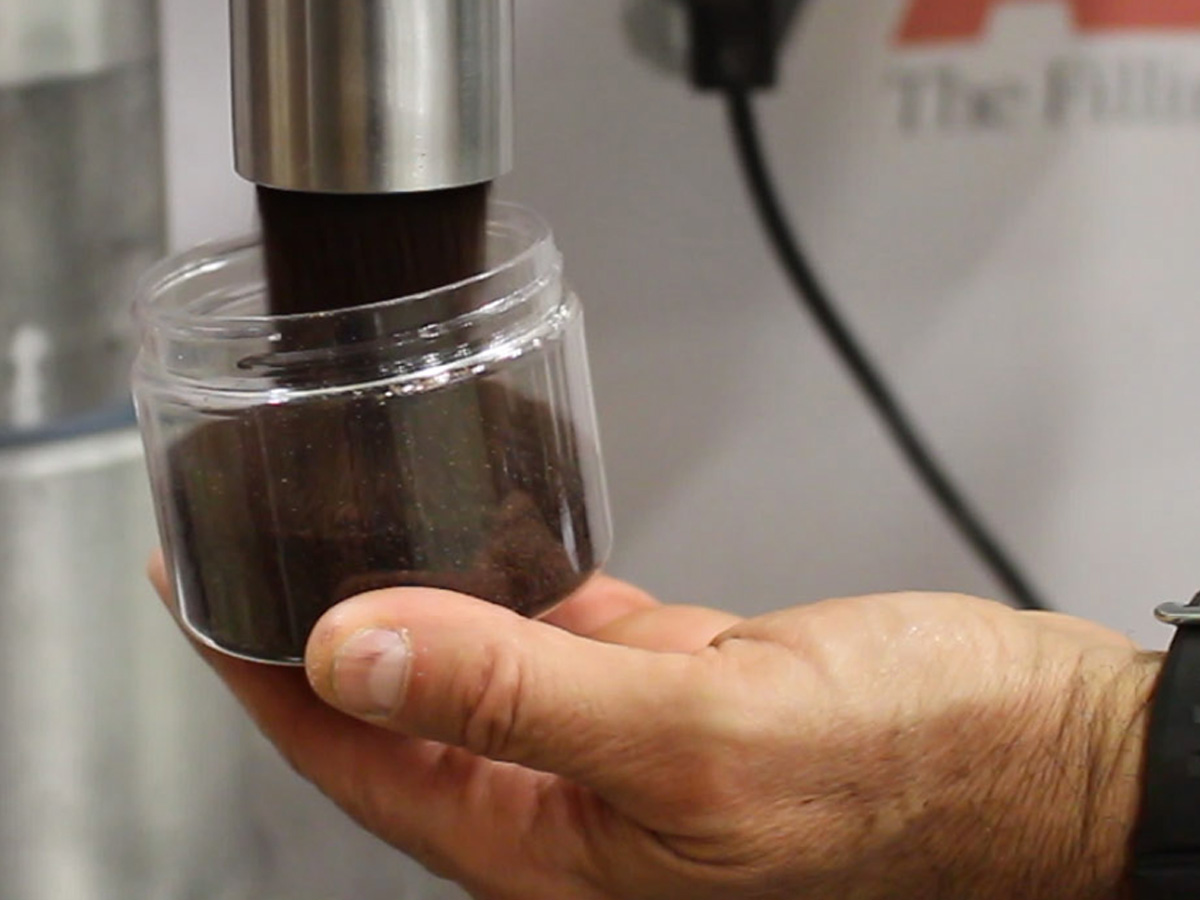

Auger Fillers

As the industry leader, our fillers are crafted for those who demand precision and reliability. Our machines stand out in handling various materials, from fine powders to granules, with unmatched accuracy.

High-Speed Rotaries

Our high-speed rotaries are expertly designed to enhance filling precision while significantly increasing production speeds, ensuring a seamless integration of efficiency and pace in your operations.

Parts & Service

AMS is committed to providing exceptional customer service meeting all your expectations with our support team, who are technically trained and knowledgeable about your equipment and applications.

Auger Fillers

The Industry Leader in Filling Equipment

The AMS auger fillers are the foundation of our filling equipment line. You can expect unmatched quality and simplicity from our machines to help improve your existing or new production lines. Our forward-thinking, design-driven engineers manufacture some of the most precise filling machines in some of the most demanding environments.

About Us

We are the Filling Machine Manufacturing Specialist

Since our founding, the AMS team and facilities have continued to grow and adapt to support our clients’ needs. Our team currently operates in our brand new 75,000-square-foot facility in Morgantown, PA. Our rapid growth results in enhanced satisfaction via a larger inventory, modern manufacturing capabilities, and strong engineering and service departments. AMS has earned its industry reputation by manufacturing a full line of custom-filling equipment. With a quick tooling change, each model can dispense products ranging from powders, granules, flakes, liquids, gels, and pastes.

The AMS auger fillers are the foundation of our filling equipment line. You can expect unmatched quality and simplicity to our machines to help improve your existing or new production lines.

About Us

We are the Filling Machine Manufacturing Specialist

Since our founding, the AMS team and facilities have continued to grow and adapt to support our clients’ needs. Our team currently operates in our brand new 75,000-square-foot facility in Morgantown, PA. Our rapid growth results in enhanced satisfaction via a larger inventory, modern manufacturing capabilities, and strong engineering and service departments. AMS has earned its industry reputation by manufacturing a full line of custom-filling equipment. With a quick tooling change, each model can dispense products ranging from powders, granules, flakes, liquids, gels, and pastes.

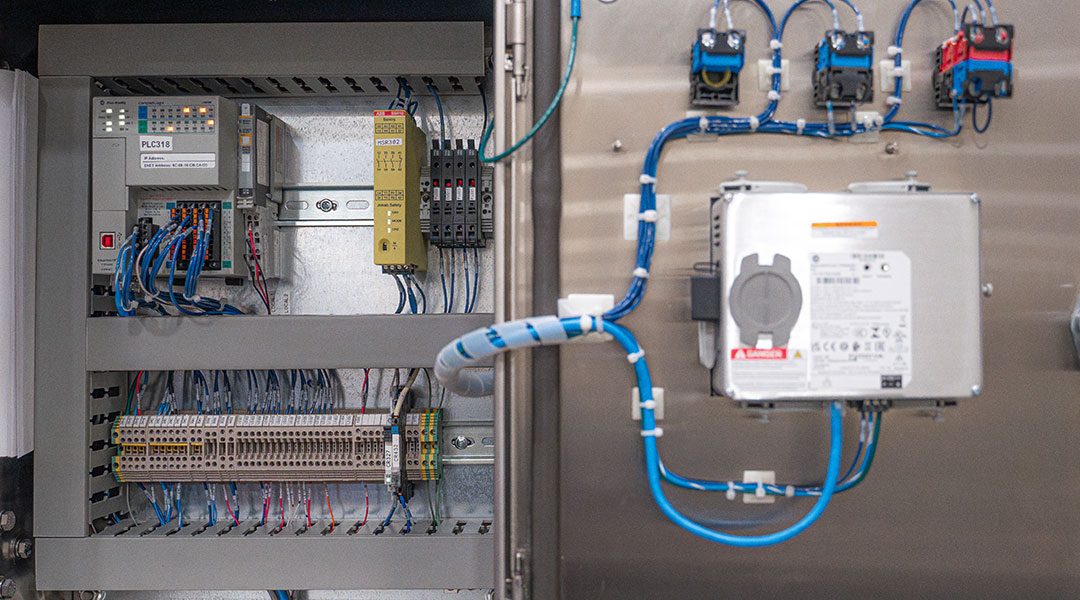

Checkweighers

We Simplify Your Process

Verify Checkweighers were developed as a complimentary line for AMS Filling Systems in response to the restrictive proprietry controls of checkweighers on the market. Our new line provides off-the-shelf components, PLC-based controls, and simple system integration. The collection consists of four models: Strain Gauge Drag Chain [EC-100], Strain Gauge Belt [EB-100], High-End Belt [HB-100], and Embedded Checkweigher. We specialize in simple, user-friendly operations with ergonomic controls and minimal operator training. Our goal is to simplify the check weighing process by customizing each machine to fit each application.