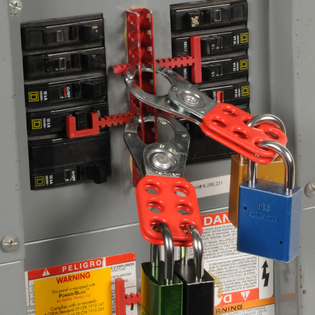

Power/Bloc by Safety Design, Inc™

Patented, Permanently-Mounted System for Circuit Breaker Lockout, Tagout

Fits panels, load centers, individual molded case breakers of any manufacturer (foreign, domestic, or custom) of any age. Ideal for retrofit of existing equipment and in specification for new equipment installation.

Mounted with industrial adhesive (3M DP 805 exceeds 1,000 lbs.) No penetrating fasteners are used and panel cover does not need to be removed for installation.

Allows independent control of each individual breaker without interference with adjacent breakers. May be used with single and multi-pole breakers.

SIMPLE TO USE –

The patented, anodized aluminum, dual-sided Power/Bloc channel with T-shaped slots is designed with no moving parts. Stoploc bars in "T", "hook" or "cap" design are made of a non-metallic, non-conductive polymer with fiberglass core and designed to restrain breaker movement horizontally or vertically. The appropriate stoploc bar restrains the de-energized breaker as it is held in place in the T-shaped slot by the padlock, group lockout hasp, or closed-door bar accessory. The breaker may be re-energized after removal of the lock and stoploc bar. A bar holder allows for storage of stoploc bars at the point of use. Staff only needs to bring their lock and tag.

Permanent installation (with adhesive exceeding 1,000 lbs.) uses no penetrating fasteneners and does not require removal of panel cover for installation.

The ease of installation and use encourages compliance and simplifies training.

MULTIPLE LOCKOUT/TAGOUT OPTIONS -

1/4" shank standard lock

Group lockout hasp for multiple personnel (also allows use with locks other than 1/4" shank)

Closed door bar option (with small three tumbler lock) for weatherproof, explosion-proof panels and high traffic areas where panel depth does not provide enough space for use of larger lock.

Effective tagout option with positive restraint using closed door bar and tag.

May be used to selectively identify critical circuits to help prevent accidental disconnection of critical processes.

POWER/BLOC IS AVAILABLE IN TWO MODELS -

Components for each model are color-coded for ease of use. Either model can be field cut from the 21” stock kit to the required length, standard precut kits are available or the factory can cut to specific length for site-specific measurements. Multiple channels may be used to extend length that exceeds 21". See Products section for 21" stock and standard precut kits.

(A site survey may be helpful. Custom cut and labeled kits for each panel or load center can be provided at no additional charge. Contact us for further information.)

The Power/Bloc™ High Profile (PBHP) Kit is designed for use with a useable panel depth (between dead front and door) of ¾” or greater. The PBHP-12 is 21” long and may be field cut to desired length. The Power/Bloc channel and stoploc bars for the High Profile kits are color-coded RED.

The Power/Bloc™ Low Profile (PBLP) Kit is designed for use with a useable panel depth (between dead front and door) of less than 3/4". The PBLP-12 is 21” long and may be field cut to desired length. The Power/Bloc channel and stoploc bars for the Low Profile kits are color-coded GOLD.

All Power/Bloc Kits include the Power/Bloc channel, stoploc bars, bar holder(s), safety yellow product label.

COST-EFFECTIVE -

Power/Bloc is provided in kit form. Each kit includes the Power/Bloc channel, assortment of stoploc bars in appropriate quantity for typical use, bar holder(s), and safety yellow product label. There is no cost after initial installation unless additional stoploc bars or other accessories are needed. These are available in the Products section.

MADE IN THE USA -

All Power/Bloc kit components are proudly made in the USA.

SOLUTIONS FOR OTHER ELECTRICAL LOCKOUT CHALLENGES -

DIN rail mounted devices, rotary operators, selector switches, custom devices, etc. Contact us for review of your specific challenge.